EMG Pro

Below are the available bulk discount rates for each individual item when you purchase a certain amount

UC Series Endmill for Steel General Suitable for application of steel & cast iron (≤48HRC) AICr series coating with high oxidation resistanc…

100% SSL Secure Connection

Wide Range of Applicable Materials

Different Milling Operations

Superior Substrates and Coatings

Unique Cutting Edge Geometry

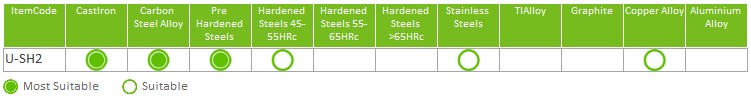

|  |  |  |  |  |  |  |  | ||

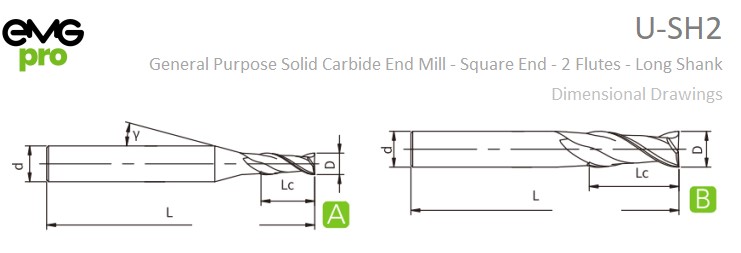

| U-SH2 Series | ≤4B HRc | Long Shank | Side Milling | Slot Milling | 35° Helix Angle | 2 Flutes | Square End | AlCrSiN Coating | Steel | Cast Iron |

Unit: mm

| Item | Series Range | EMG SKU Order Code | Ordering Code (MPN) | Profile Type | Mill Dia. (mm) [D] | Length of Cut (mm) [Lc] | Overall Length (mm) [L] | Shank Dia. (mm) [d] | Corner Radius (mm) [r] | Ball Radius (mm) [R] | Chamfer (mm) [C] | Neck Length (mm) [L1] | Neck Diameter (mm) [d2] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | U-SH2 | XI_EMG_U-SH2-02006 | U-SH2-02006 | A | 2 | 6 | 75 | 4 | - | - | - | - | - |

| 2 | U-SH2 | XI_EMG_U-SH2-03009 | U-SH2-03009 | A | 3 | 9 | 75 | 4 | - | - | - | - | - |

| 3 | U-SH2 | XI_EMG_U-SH2-04011 | U-SH2-04011 | B | 4 | 11 | 75 | 4 | - | - | - | - | - |

| 4 | U-SH2 | XI_EMG_U-SH2-05020 | U-SH2-05020 | A | 5 | 20 | 75 | 6 | - | - | - | - | - |

| 5 | U-SH2 | XI_EMG_U-SH2-06020 | U-SH2-06020 | B | 6 | 20 | 100 | 6 | - | - | - | - | - |

| 6 | U-SH2 | XI_EMG_U-SH2-08025 | U-SH2-08025 | B | 8 | 25 | 100 | 8 | - | - | - | - | - |

| 7 | U-SH2 | XI_EMG_U-SH2-10030 | U-SH2-10030 | B | 10 | 30 | 100 | 10 | - | - | - | - | - |

| 8 | U-SH2 | XI_EMG_U-SH2-12035 | U-SH2-12035 | B | 12 | 35 | 100 | 12 | - | - | - | - | - |

| 9 | U-SH2 | XI_EMG_U-SH2-14036 | U-SH2-14036 | B | 14 | 35 | 150 | 14 | - | - | - | - | - |

| 10 | U-SH2 | XI_EMG_U-SH2-16036 | U-SH2-16036 | B | 16 | 36 | 150 | 16 | - | - | - | - | - |

| 11 | U-SH2 | XI_EMG_U-SH2-18045 | U-SH2-18045 | B | 18 | 45 | 150 | 18 | - | - | - | - | - |

| 12 | U-SH2 | XI_EMG_U-SH2-20045 | U-SH2-20045 | B | 20 | 45 | 150 | 20 | - | - | - | - | - |

The EMG Edge U-Series of end mill are a general purpose solid carbide end mill range from EMG Precision. Part of the 'EMG Edge' Series of professional milling cutting tools.

The U-Series are suitable for semi-finishing and fine finishing of general steel, cast iron and stainless steels up to 48 HRc. Comfortable face milling with a small depth of cut (ap) and a large width of cut (ae). Capable of shallow slotting at less than 0.5D.

Ultra-fie grained carbide substrates provide excellent hardness. AlCr-based coatings are applied along with Balzers latest KiLA furnace, providing high stability, good resistance to heat and wear and tear. The optimal geometry ensires the strength and sharpness of the cutting edge.